Coiled tubing negative pressure drilling sand washing equipment in ji well 7h petro China CNPC

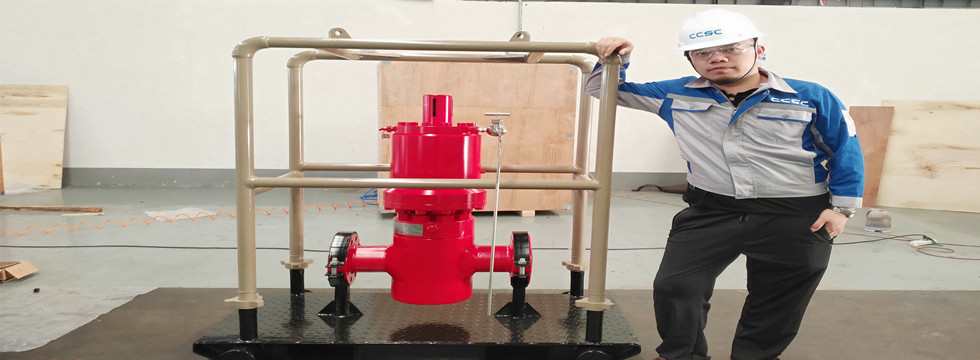

Recently, our coiled tubing negative pressure drilling and sand washing equipment was applied in the ultra-deep and ultra-high temperature natural gas well Ji 7H for the first time. All construction parameters met the design requirements and achieved great success. The product packages we provide this time include fracturing wellheads, fracturing manifolds, plug valve manifolds, fracturing valves, fracturing heads, fracturing trees, fluid pipelines, wellhead control panels, desanders, desanding manifolds, ESD Control Panels, Cyclone Desanders, Frac Gate Valves, Frac Check Valves, Frac Plug Valves, Fluid Lines, API 6A Valves and more.

The Ji 7H well is a risk exploration well in the Turpan-Hami Basin in 2021. The well is 6,120 meters deep and has a high temperature of 150 degrees Celsius. It is an ultra-deep and ultra-high temperature natural gas horizontal well. In order to realize the next benefit development of the Ji 7 block, the Tuha Oilfield decided to drill and flush the sand after removing the hydrate in the well.

Well Ji 7H is a high-yield condensate oil and gas well, with a narrow time window for the formation of hydrate at the wellhead, resulting in a narrowing of the diameter, which is extremely rare in domestic onshore oilfields. The difficulty is that the tool cannot be run in, and the pressure difference of the liquid column cannot be controlled accurately, which will easily lead to the risk of sticking during the construction, lost circulation and the risk of blowing out after the production is put into operation. The current conventional process is difficult to meet the needs, and finally decided to use the coiled tubing hot washing. + Negative pressure drilling and sand washing technology to achieve production capacity recovery.

After receiving the construction task of the well, the construction company attached great importance to it, organized the docking party in advance, and communicated and coordinated technical matters. A special leading group was established, and several promotion meetings were held to plan the required equipment and materials in advance. The participating units scientifically allocated resources, selected elite soldiers, and made every effort to ensure a strong and orderly production organization. Our coiled tubing negative pressure drilling and sand washing equipment assists the safe, high-quality and efficient construction of Ji 7H well.

In order to minimize the pollution and damage to the reservoir after the circulating fluid invades the formation, and to avoid the impact on the gas well production after the measures, the Tuha Downhole is based on "underbalanced and non-stop production", and has carried out joint technical research with the "two institutes and one center" of Western Drilling, and organized many times. A seminar and collaboration meeting on the underbalanced (negative pressure) technical solution of low-density foam circulating fluid were held to comprehensively analyze the geological well history data in the block and accurately evaluate the formation pressure; combined with laboratory evaluation and software-assisted analysis, evaluate the high-temperature oil-resistant foam drainage To improve the foaming performance and foam-stabilizing performance of the agent, optimize the formulation of the low-density foam killing fluid system, and provide a working fluid system with good sand-carrying performance, foaming performance and foam-stabilizing performance for drilling plugging and sand flushing operations in Ji 7H Well, and further improve the Ji 7H well. 7H construction plan

Well Ji 7H adopts the self-developed compound low-density foam circulating fluid underbalance (negative pressure) technology for the first time. With the help of our coiled tubing negative pressure drilling sand flushing equipment, the outlet density is controlled at 0.6~0.7 during the sand flushing drilling and grinding process. For the first time, a high-pressure cyclone desander is used to realize continuous online sand removal; for the first time, two sets of ground throttling manifolds and three-phase separator control are adopted to realize continuous online production and direct oil and gas entering the station. Before construction, technicians adjusted the performance of the low-density circulating fluid system, continuously optimized foaming, foam stabilization time, and suspended sand conditions. Engineers intervened in advance and carried out on-site preparations to ensure that preparations were in place

With the help of our coiled tubing negative pressure drilling sand washing equipment, along with 7000 meters of continuous oil running, the hydrate was successfully drilled by circulating hot washing with 85 degrees Celsius circulating fluid, and the replacement density was uniform and the displacement was stable. The low-density foam circulating fluid was injected into the wellbore, and the upper and lower movable strings were used to test the suspension weight and foam fluid performance. Well Ji 7H started the coiled tubing nitrogen foam drilling plug and sand flushing operations. After five hours, the outlet density was 0.67 g/m3. The outlet viscosity is 53mPa.s, which meets the construction requirements. The two-stage pressure control technology is used for stable pressure control throughout the construction process to form a negative pressure difference. The annulus return rate of this well is greatly increased compared with the previous one, which effectively improves the displacement efficiency under the condition of easy leakage. The temperature resistance, oil resistance, stability and sand-carrying property of foam workover fluid were tested twice in different well sections.

Two days after the sand flushing operation in Well Ji7H, the circulating material met the construction expectations, and natural gas and crude oil were produced from time to time, which fully proved that the foam workover fluid not only met the well control requirements but also protected the reservoir.

The coiled tubing negative pressure drilling sand flushing technology in Well Ji7H was successfully applied, and accumulated experience for unconventional negative pressure and underbalanced operations for the Qiusha No. The valuable experience provides a favorable guarantee for further improving the wellbore treatment of coiled tubing in ultra-deep and ultra-high temperature natural gas horizontal wells, and at the same time lays a solid technical foundation for the popularization and application of low-density foam circulating fluid in Tuha Oilfield.

Our coiled tubing negative pressure drilling and sand washing equipment has been applied very successfully in the Ji 7H well of PetroChina Tuha Oilfield, and has been well received by customers and highly praised.

All Rights Reserved, Copyrights@ccscpetro.2022.07 Contact Email: clarkoilgas@qq.com

Poster发布人: Clark Guo, CCSC Technology, Shanghai, China, 2022.07 Youtube: Clarkwellhead

Wechat & WhatsApp: +86 13764749879 Email: clarkoilgas@qq.com

Keywords关键词: shale gas,coiltubing,fracturing,Ultra-deep horizontal well,coil tubing bop,flowline treating iron,API 6A valves,frac valve,frac head,frac tree,frac check valve,frac gate valve,frac plug valve frac manifolds,plug valve manifolds,spools,weco unions,plug catcher,debris catcher,sand catcher,sand filter,sand cyclone,wellhead control panel,ESD control panel,wellhead christmas tree.

►Youtube: Clarkwellhead